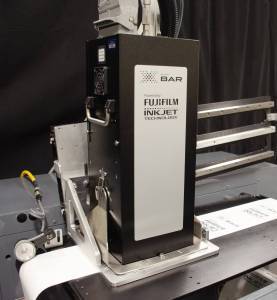

Quality, speed, and flexibility are of prime importance in label printing with the X-BAR print module emerging as a winner. It is positioned to reshape traditional label production processes. It offers an integrated solution for inline digital printing of variable data on analog printers.

The Challenge of Variable Data Printing

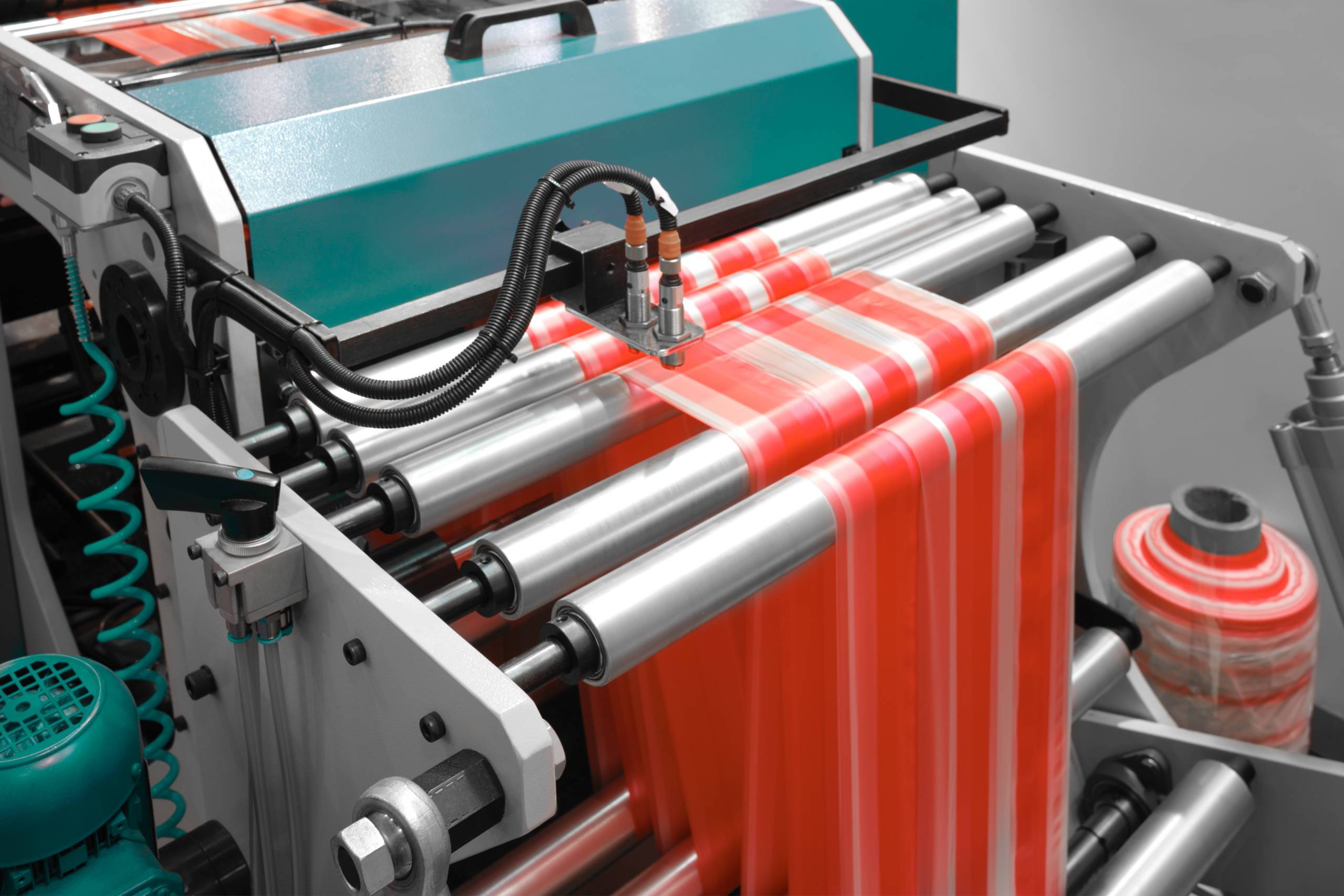

Traditional analog printers remain cost-effective workhorses for producing consistent design and label graphics over long production runs. They face the obvious limitation of producing variable data such as SKUs, addresses, barcodes, and other dynamic information.

On the upside, flexo printing of labels is cost-effective for longer production runs because nothing changes. That is also the downside without the addition of inline digital printing.

Without inline digital printing, label producers operate less efficiently.

This requires a disjointed production process for variable data printing in a second step on digital printers or outsourcers, which increases costs and potential errors.

The demand for personalized and dynamically updated labels is rising across various industries, from food and beverage to pharmaceuticals and logistics.

Printing companies are increasingly pressured to find solutions that efficiently integrate variable data into their analog workflows.

Adding a primary or secondary digital printer can be cost-prohibitive.

Introducing Inline Printing with X-BAR

The X-BAR, Powered by Fujifilm Inkjet Technology, offers a solution for upgrading flexo or offset printers with bolt-on digital printing units for inline variable data printing. X-BAR enables companies to adapt existing analog printers.

Inline production refers to integrating printing or other finishing embellishments into a single, continuous process. This means that labels can be printed with static elements (logos, graphics, and branding) on the analog system and variable data (such as product information, barcodes, and batch numbers) in one continuous operation.

X-BAR technology makes this possible by incorporating advanced print modules and software solutions synchronizing variable data printing with the rest of the label content. This eliminates the need for separate printing steps or equipment, streamlining production workflows and significantly improving efficiency.

Retrofitting flexo or offset printers with high-speed X-BAR technology extends the capabilities of analog printers by introducing hybrid printer concepts. A hybrid printer combines the best of analog and digital printing technologies, allowing companies to leverage the speed and quality of analog printing with the flexibility and versatility of digital variable data printing.

Benefits of X-BAR for Inline Printing

Users have found that the 1,200 dpi X-BAR print module for inline printing delivers on the promise of a cost-effective solution that integrates with existing equipment printing processes, enabling customization and minimizing downtime.

Lower Capital Investment

Using X-BAR print modules for inline printing eliminates the need for separate printing processes or new high-cost equipment, reducing production time and operational costs. Companies can now produce labels with variable data seamlessly integrated into the design, ensuring consistency, accuracy, and faster turnaround times.

Flexibility and Customization

With the addition of X-BAR inline printing, companies can respond rapidly to changing customer demands and market trends. With the flexibility to incorporate personalized elements, variable data, and on-the-fly updates, printing companies can offer tailored solutions that resonate with their customers and drive engagement.

Accelerated ROI

Implementing X-BAR technology in label printing operations leads to significant cost savings through efficient consumables management, minimized waste, and increased speed. Customers benefit from reduced ink and substrate usage, lower operational expenses, and extended run times between maintenance cycles. This combination of cost efficiency, waste reduction, and enhanced productivity accelerates your ROI.

Reduced Downtime

X-BAR technology minimizes downtime and maximizes productivity. With fast restarts, zero charge shorts, and zero streakers, X-BAR ensures continuous operations, reducing disruptions and optimizing uptime. This results in enhanced productivity, smoother workflows, and meeting production targets.

Retrofitting Analog Printers with X-BAR Print Modules

The X-BAR print module converts an analog label printing system into a hybrid printer to add variable data.

One aspect of X-BAR technology is its compatibility and ease of integration with analog printers. Companies can retrofit their analog systems with X-BAR print modules, unlocking inline printing capabilities without requiring extensive modifications or investments in new equipment.

The retrofitting process involves integrating X-BAR print modules, software solutions, and workflow enhancements into the existing printing infrastructure. This ensures a smooth transition to inline printing while leveraging the full capabilities of X-BAR technology.

Several critical considerations come into play when upgrading a flexo or offset printer with digital capabilities.

When upgrading your analog printer, consider these key factors: inline placement, space allocation, maintenance access, and substrate path alignment.

Our engineers can discuss these with you in more detail.

Future Trends in Label Printing

Inline digital printing technology is reshaping label production, offering efficient processes and rapid customization to meet market demands effectively.

This adaptation aligns with other trends toward on-demand manufacturing and e-commerce, where flexibility and agility in label printing are essential. X-BAR technology supports this capability, enabling companies to produce labels in response to real-time demand, minimizing inventory overheads, and maximizing production efficiency.

Beyond on-demand production, the X-BAR supports sustainability, which is another industry imperative as consumers and regulators pressure companies to adopt eco-friendly solutions. By utilizing water-based inks and more efficient production processes, X-BAR enables companies to adopt greener practices and contribute to a more sustainable label printing ecosystem.

Changing Printing and Changing Business

Efficiency, personalization, and sustainability converge, making X-BAR a game-changer for label printing as the unassuming component transforms production. The cost-effective addition to analog printers transforms printing and energizes business.

Contact Kao Collins to explore X-BAR inline printing solutions, request demos, or schedule consultations. Also, ask about the Universal Controller, another game-changer.