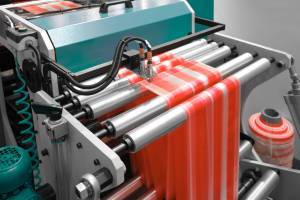

In the fast-moving present times where “Speed is King,” everyone wants fast solutions and faster services from top speed cars to fast-paced computers. Print technology and advanced printing systems are also running at higher speeds to increase productivity, and inks have to keep up with the increasing market demands.

The Demand for High-Speed Printing

Industrial inkjet printers print at higher speeds without losing quality to compete with flexo and offset printing. Other factors push OEMs to develop faster industrial inkjet printers.

Driving The Push for Faster Inkjet Printers

Kao Collins Fast-Drying Inkjet Inks

Download

- Integrated automated production systems

- Compensate for growing SKU production

- eCommerce growth

- Mass customization

- Improving ROI

- Grow adoption over analog printing

This leads to a heavy demand for fast-drying inks, saving valuable time to scale up productivity without compromising print quality.

The Demand for Fast Drying Inks without Compromises

Faster drying or curing inks may help reduce the risk of ink migration.

As industrial inkjet printing technology improves, ink must also improve for printers to benefit from innovation.

The technological progress has been in increasing print speeds and minimizing all other risks from the ink, for example, in food packaging. One of the challenges in the printing industry has been improving ink drying and its impact on print performances.

Reduced ink drying and curing time must increase; otherwise, faster printing does not mean increased production or efficiency–and in some cases could compromise safety concerns like ink migration risk.

More industrial inks offer superior drying capabilities that support the latest printing technologies and prevent the risks of ink migration.

Types of Ink Drying or Curing

Three drying or curing methods comprise assisted or unassisted drying. Most printers may combine several processes to achieve optimal drying or curing.

Absorption

Absorption

Unassisted absorption is time-consuming and may allow the accumulation of solvents in the substrate. The process requires a porous substrate.

Production printers often incorporate assisted drying systems to speed drying on porous substrates.

Radiation

Radiation

Radiation curing incites a chemical reaction that initiates a polymerization, turning the liquid into a durable solid. UV-curable inks incorporate photoinitiators that react to ultraviolet light from mercury arc or LED lamps.

Electron-beam curable inks (EB-curable) rely on initiators that react to electron beam energy.

Evaporation

Evaporation

Most production inkjet printing relies on assisted or unassisted evaporation for ink drying. As most of the ink evaporates, only a thin film of colorants and binders remain on top of or somewhat absorbed into the substrate.

The challenge of evaporation requires introducing heat while preserving substrate moisture or causing other damage.

What Affects Ink Drying or Curing?

While the type of substrate remains the most important factor that affects ink drying or curing, some other equally important factors include:

Humidity

Relative humidity can cause the substrate to become damp and limp. Ink takes a long time to dry on paper in this condition. The effect of moisture on drying is the same, whether it comes from paper or the atmosphere.

Relative humidity can cause the substrate to become damp and limp. Ink takes a long time to dry on paper in this condition. The effect of moisture on drying is the same, whether it comes from paper or the atmosphere.

This situation can be corrected by controlling the relative humidity and introducing warmth immediately after printing.

Temperature

Ink dries faster on warm stock than on cold. The drying time improves by about 25% for each 42°F (6°C) increase in temperature. This is true for inks that dry by absorption or oxidation. Heat lowers the viscosity of absorbing inks, and to an extent, the surface tension of the substrate. Heat accelerates the chemical reaction of inks that dry by oxidation.

Ink dries faster on warm stock than on cold. The drying time improves by about 25% for each 42°F (6°C) increase in temperature. This is true for inks that dry by absorption or oxidation. Heat lowers the viscosity of absorbing inks, and to an extent, the surface tension of the substrate. Heat accelerates the chemical reaction of inks that dry by oxidation.

Amount of Ink Deposited

Controlling the amount of ink deposited helps optimize drying time. Applying only the amount of ink necessary improves drying performance. Beyond improving drying time, managing correct ink coverage that achieves the desired results saves ink costs and supports sustainability.

Controlling the amount of ink deposited helps optimize drying time. Applying only the amount of ink necessary improves drying performance. Beyond improving drying time, managing correct ink coverage that achieves the desired results saves ink costs and supports sustainability.

Benefits of Fast-Drying Inks

At a quick glance, some of the benefits of fast-drying Inks are as follows:

- Achieve faster production line speed

- Reduces risk of ink migration

- Supports sustainability with less energy used for drying systems

- Better resistance to environmental conditions

- Smear and smudge resistant

- Higher durability

Fast-Drying and Fast-Curing Inkjet Inks

Inkjet inks are described by their carrier fluids or their properties. Drying systems can be functional alone on the surface of the printing substrate for an ink film or depending on the chemical content of the ink and the properties of the printing substrate. In other words, industrial printers can achieve fast drying by combining the properties of the substrate with the properties of the ink accurately.

Some commonly found inkjet ink types that dry fast include:

Solvent Ink

These inks use a petroleum-based solvent as the carrier fluid. The solvents dry very quickly through assisted or unassisted evaporation on non-porous, glossy, or coated substrates.

Solvent inks are economical and durable, and they can print on non-porous substrates, including plastics, glass, and metals. Solvent inks release volatile organic compounds (VOCs), making them less environmentally friendly.

Solvent inks enclosed in thermal inkjet (TIJ) cartridges significantly reduce VOC emissions compared to continuous inkjet (CIJ) systems that rely on recirculating solvent inks. The solvent carrier fluid influences drying times.

Solvent ink formulations often incorporate alcohols and ketones. Depending on the carrier fluid, assisted dry times of less than one second can be achieved, depending on the substrate.

LED Curable Ink

LED UV curing uses high-intensity electronic ultraviolet (UV) light from energy-efficient LED lamps that cause a photo-reaction. LED inks instantly transform from liquid to solid in the curing process.

Low Migration UV/LED Ink

Low migration inks require raw materials and chemistries with higher molecular weight for optimal curing to reduce the risk of compounds or elements passing from the substrate to the product.

Inks comprise only one factor in evaluating migration. Independent testing for ink migration should be conducted to evaluate the interaction of the ink, substrate, environmental conditions, and even end-use.

Due to the inherent risks associated with inks migrating into the product, the inks must comply with an array of guidelines and ordinances.

These inks support numerous other industries, including pharmaceuticals, cosmetics, and more. Suppliers and converters need to ensure that every food package protects the consumer’s health, and ink plays a central role in that process.

UV Curable Cationic Ink

Among the curing processes, cationic UV curing has numerous advantages over conventional thermal curing. In particular, photopolymerization has low volatile emissions, fast curing speed, and no shrinkage.

UV Curable Free Radical Ink

When UV exposure is initiated for curing, certain free radical generating photoinitiators are cured through double bonds with two photoinitiators.

What happens during this process?

- Photoinitiator absorbs UV light energy creating radicals.

- Radicals react with acrylate monomers and oligomers, inducing crosslinking.

- Liquid resin system converts to dry/cured product on crosslinking.

EB (Electron Beam) Curable Ink

The past several years have brought rapid electron beam (EB) technology changes, making EB curing a more practical alternative to traditional ink curing methods.

Unlike UV-curable inks, EB inks don’t require photoinitiators. The oligomers and monomers polymerize from exposure to a beam of high-energy electrons.

Benefits of EB-Curable Inkjet Inks

- No photo initiators reduce the risk of ink migration

- Useful for food and pharmaceutical packaging

- Deep ink-to-substrate bond.

- Instant curing

- Free of VOCs

- Substrate doesn’t affect the curing

Water Based Ink

Numerous variables can affect the drying performance of water-based inkjet inks. Assisted evaporation produces the fastest drying of water-based inks, often less than one second, depending on the substrate. Forced warm-air dryers quickly evaporate the water carrier fluid. Infrared lamps dry water-based inks more slowly, impacting line speed.

We Collaborate with OEMs

Ink manufacturers work closely with printheads and printer OEMs to formulate inks that match increasingly faster industrial inkjet printing systems. Kao Collins chemists and engineers work closely with OEMs to develop high-performance inks compatible with the newest industrial printing equipment.

Contact us to discuss your options for fast-drying inks for your printing application.