Digital printing quality has a lot to do with the choice of ink and formulation characteristics. Every component of the ink delivery system, including nozzles, pumps, reservoirs, etc., is equally important.

Your inkjet printer’s delivery system should be the first place you look for causes of ink dropout and starvation. Both issues are headaches that cost time and waste materials. Here’s a thorough look at how you first identify, then remedy the causes of ink dropout and starvation.

Dropout and Starvation are Two Sides of the Same Coin

The causes of ink dropout and starvation are different, but their effect on the final printed results is the same: They lead to poor-quality printing.

What is Ink Dropout?

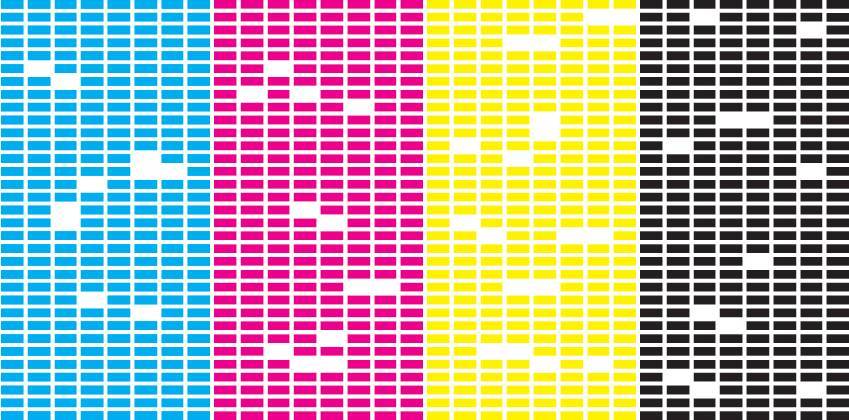

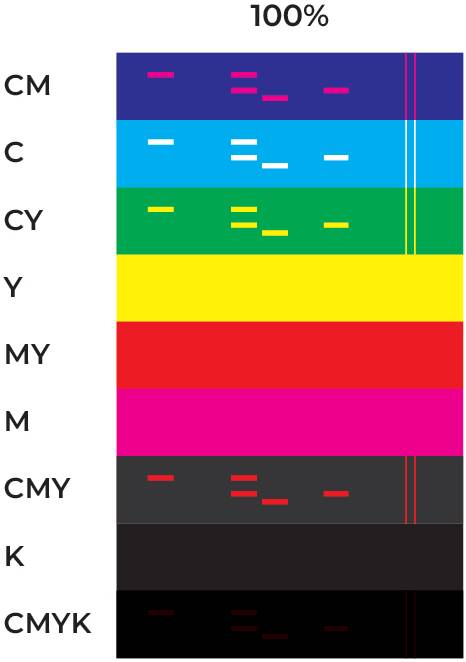

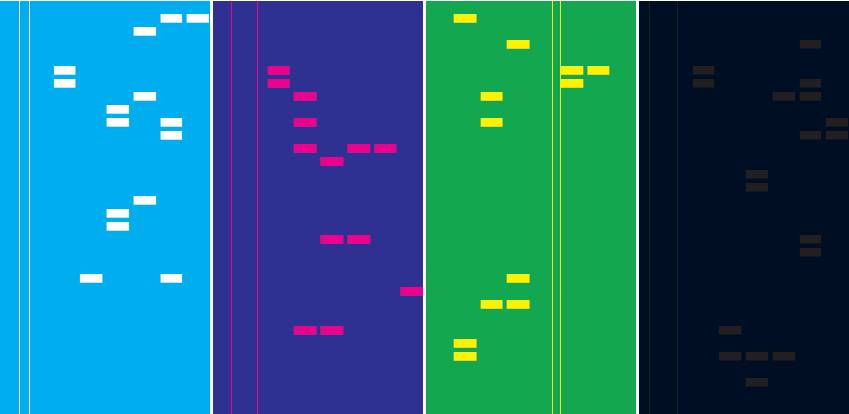

Dropout refers to the issue of one or more ink nozzles in the printhead failing to fire, resulting in missing or incomplete printing in those areas.

What is Ink Starvation?

Starvation refers to a lack of ink flowing to the print head, resulting in missing or incomplete printing.

How Do You Identify Dropout or Starvation?

There are two simple indicators of a dropout. You’ll see the telltale sign of ink dropout or starvation when an area of a digital print fades or is entirely devoid of color. It is a common problem with wide-format printers. In some cases, dropout manifests as a fading color output; in extreme cases, the whole image area is not printed.

The Costs of Ink Dropout and Starvation

One word sums up the downside of dropout and starvation: Waste. Catching the signs of these problems early reduces their costs. Here’s a look at how these costs add up for businesses that rely on inkjet printing.

Lost Money

Ink starvation and dropout lead to downtime, which has ripple effects on your business and production. The bottom line of this is loss of money. If ink is the root cause of dropout, looking for savings with inferior, low-cost ink may end up costing you more.

Wasted Materials

Beyond ink, dropouts waste printing materials such as paper, labels, boxes, etc. That doesn’t include the time needed for make-good production in the wake of a dropout.

The Causes of Ink Dropout and Starvation

System Configuration

Faults with drivers and the printer software can cause dropout. It is essential to have the appropriate system configuration to prevent dropout. There must be smooth communication between the computer and the printer to ensure quality printing.

It is essential to have the appropriate system configuration to prevent dropout. There must be smooth communication between the computer and the printer to ensure quality printing.

Air in the Line

The ink delivery system of printers requires pressure to function. A slight amount of air in the line will distort the ink delivery. The inkjet system uses air pressure to move the ink out through tiny nozzles onto the media. Any internal air bubble in the line will hamper affect pressure leading to ink starvation. Air can get in the ink supply line with faulty dampers, cracked tubing, or loose connections.

Cartridge Improperly Primed or Seated, or Low Ink

The ink cartridge is another critical piece of hardware in the printing line. Improper priming or seating of the cartridge can result in starvation. The obvious cause is when the ink level is low, or the cartridge is empty.

Defective Cartridges

The cartridge sits in a printhead that delivers the ink via a nozzle. A damaged or defective cartridge will not supply ink appropriately. Also, using an incompatible cartridge will cause inconsistent or total loss of ink delivery. Choose ink suppliers like Kao Collins that use factory-new OEM cartridges.

Idle Printer

When a printer is idle, the damper may become dry. The damper traps air from the line to keep the pressure in check. An idle printer can also cause the cartridge and printhead to dry out, resulting in dropout.

Improper pressure settings for the type of ink being used

Air pressure is significant in the ink delivery system. Ideal pressure ensures the level that each ink type requires for proper delivery. Once the pressure setting is wrong, the ink will jet properly. Seasonal conditions also affect system pressure and ink delivery.

Residue Buildup clogs the nozzle

SIGMA INKS 12-Hour Decap

Learn More

Residual ink buildup in the nozzle can cause blockage. Clean the nozzles and printhead after each printing run since built-up ink along the nozzle or printer head will affect precision jetting. Some ink manufacturers formulate inks with extended decap times that reduce the need for wiping and purging printheads.

Solutions for Dropout and Starvation

Preheat Setting

Preheating the printer before starting a printing job warms up the print bed and extruder. During the preheating, the cartridge and filament are prepared and primed for proper ink delivery.

Bleed Air from the Line

Air in the printing line is a significant cause of starvation. When a dropout or ink starvation is noticed, clear the line of any air bubble that may have been trapped in the line. Replacing the damper may be necessary to solve the problem of ink starvation.

Perform Powerful Cleans

Refer to your printer’s operating manual and conduct electronic cleaning to remove any ink residue or contaminants. Perform printhead cleaning until the nozzle check is acceptable. Physical cleaning of the cartridge and the wiper blades also help to control ink starvation.

Repair or Replace Faulty Components

The cartridge and damper are essential components to prevent dropout. Replace or repair defective cartridges or dampers in any case of ink starvation or dropout. Use the correct type of these components to prevent further complications in the ink delivery system.

Purge and Wipe Printhead

Wipe excess ink and spills on the printhead with a lint-free material. Cleaning the printhead removes any debris that can block the flow of ink.

Quality Inkjet Inks and Experts That Help

At Kao Collins, we use factory-new OEM cartridges with inks formulated for the leading printhead technology. Our experts can help you identify and solve ink dropout and starvation problems. Contact Us.