Spurred by the demands of online retailers, especially behemoths like Amazon, inkjet printing increasingly delivers the solution for printing corrugated cardboard boxes in the need-it-now economy when costs of freight and other factors are added to the calculus.

Kao Collins Inkjet Inks Reduce Risk of Ink Migration

Download

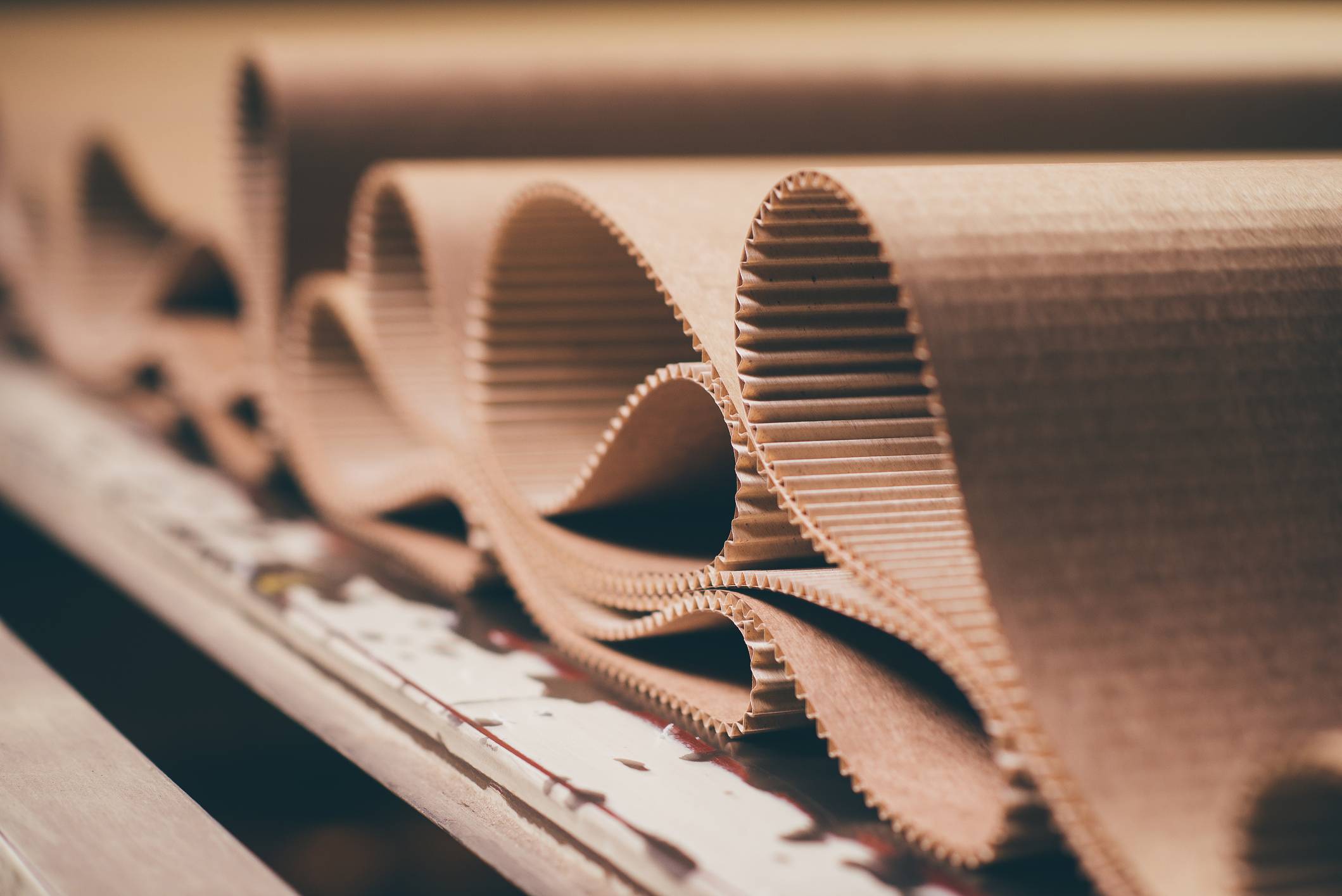

The utility of the humble cardboard box hasn’t changed much since its introduction in 1891. Cardboard boxes today withstand considerable human and natural forces. The inks for printing labels, logos, and other information must be equally durable.

Challenges for Inkjet Printing Cardboard Box Printing

Printing on plain brown boxes or even “up-scale” boxes must last long enough not to rub off, remain legible, and offer a level of visual appeal when necessary.

The boxes endure assembly lines for packing and shipping, whether through the slower ground delivery to next-day and now same-day delivery. The printing on all those boxes must withstand temperature fluctuations and human handling. Also, the printing must resist quick fading or effects nature’s elements.

Choose Inks for Printing on Cardboard

Personalized messages on cardboard packaging create a customer connection. Printing on the glossy finish requires an ink appropriate for that substrate.

Some box finishes require extra consideration when choosing an ink. While many boxes are the traditional dull, brown, some businesses expect more and opt for boxes with a better finish for that branded look. These boxes often have a layer of semi-gloss white, or another color, paper over the corrugated cardboard. Inkjet ink manufacturers evaluate the substrate to deliver the best ink for the corrugated material.

Curing is another consideration in the ink formulation. The inks must dry on the substrate quickly in high-speed production systems yet remain fluid on the printheads to avoid costly downtime for upkeep. Various curing systems are used across the industry, depending on the ink: forced air, ambient air or dryer.

Most of the inks used are water-based inks, which are typically cheaper than UV or solvent-based inks.

DOWNLOAD: Benefits of LED-curable ink for cardboard

Dye or Pigment Inkjet Ink?

Generally, most inks used for box printing are pigmented. Marking and coding on corrugated boxes use black piezo inkjet inks, which are traditionally oil-based pigment inks and now an eco-friendly bio-based mineral-oil-free ink. For marking and coding with thermal inkjet systems (TIJ), many printers employ water-based pigment or dye-based inks.

Dye formulations are used most frequently in inkjet printing on cardboard. These formulations are less opaque but absorb well into the box.

While most inkjet printing on cardboard projects are using black ink, a company may want its logo to reflect its identity through its brand color. Companies like Kao Collins analyze the color characteristics of the substrate to formulate an ink that matches the intended brand color.

We’re here to help formulate inks for corrugated packaging and point of sale materials.

Contact Us

Shifting Technology

Companies are opting for inkjet printing over the long-time methods of flexography, rotogravure and offset.

Until recently these legacy systems have had the advantage because they were cost-effective for high-speed, high-volume production. Massive printing presses produced the boxes that were shipped anywhere to the customer. The scale and volume of production justified the expensive printing infrastructure.

Using inkjet technology for cardboard printing allows companies to be nimble in producing boxes and avoid over-or-under-forecasting the amount of cardboard they’ll need.

Needs have changed

Businesses are demanding more flexibility. With the growth of e-commerce and related shipping, companies are choosing inkjet. Companies are reluctant to lock into large orders of boxes based on speculation of consumer demand for products. Additionally, businesses are weighing the cost of the freight and warehousing of boxes.

Read: 5 Ways To Wow Customers with Inks for Cardboard Packaging

Companies can affordably set up an inkjet printing operation for box production. And digital inkjet can be reconfigured more quickly. Digital inkjet printing opens the door for personalized messages on shipping boxes.

As inkjet technology continues to be more widely adopted, it can no longer be viewed as a printing option with only a few, specific uses. Indeed, with a little out-of-the-box thinking, inkjet printing will continue to flourish.