Dec 1, 2023

Sustainable Packaging Regulations Coming For Cosmetics and Beauty Brands in 2024

Like other consumer segments, the beauty and cosmetics industry faces regulatory scrutiny. At issue heading into 2024 is the increasing demand for sustainability for cosmetics packaging.

The European Union and the United Kingdom are gearing up to implement stringent sustainable packaging regulations. This trend is pivotal for beauty brands and business services like the industrial inkjet printing industry. Regulations create opportunities for inkjet ink manufacturers to help the beauty industry comply.

Inks for Cosmetics Packaging

Purchase Inks

This article explores the impending regulatory measures and some of the innovative packaging solutions enabling beauty companies and supplier partners to navigate sustainability demands for waste reduction.

Industrial Inkjet Printing Supports EU and UK Sustainable Standards”

In this section, we’ll explore the key elements and requirements of the UK’s Extended Producer Responsibility (EPR), the EU’s ESPR (Ecodesign for sustainable products regulation), and the EU’s Packaging and Packaging Waste Regulation (PPWR).

1. UK – Extended Producer Responsibility (EPR)

The UK’s EPR regulations align with the country’s long-held support of environmental sustainability. Beauty brands operating there must adhere to the Extended Producer Responsibility requirements, participating in funding recycling initiatives and adopting more eco-friendly packaging materials for easier recycling.

The UK’s EPR regulations align with the country’s long-held support of environmental sustainability. Beauty brands operating there must adhere to the Extended Producer Responsibility requirements, participating in funding recycling initiatives and adopting more eco-friendly packaging materials for easier recycling.

The implementation of Extended Producer Responsibility regulations will be fully implemented by 2027.

UK beauty brands must collect data from January 1, 2023, to ensure compliance with the new regulations. They will need to account for the total costs of recycling and recovery, purchase Packaging Recovery Notes (PRNs), and invest in recycling awareness programs.

What the UK EPR Framework Means for Beauty Product Packaging in 2024 and Beyond

| EPR Action | Description |

|---|---|

| Data Collection and Reporting | Beauty brands must begin by collecting and reporting data regarding their packaging use. This data should comprise details about packaging materials, formats, waste streams, packaging components, recycling disruptors, recycling enablers, and material colors. |

| Enhanced Recycling Commitment | The UK’s Extended Producer Responsibility (EPR) framework in 2024 signifies a renewed commitment to sustainable practices within the beauty industry. UK beauty brands must prioritize recyclable packaging materials, promoting a greener and more eco-friendly approach. |

| Data Collection and Reporting | Beauty brands must begin by collecting and reporting data regarding their packaging use. This data should comprise details about packaging materials, formats, waste streams, packaging components, recycling disruptors, recycling enablers, and material colors. |

2. EU – Ecodesign for Sustainable Products Regulation (ESPR)

The Ecodesign for Sustainable Products Regulation (ESPR) represents a significant shift in the regulatory landscape for beauty brands operating in the EU.

The Ecodesign for Sustainable Products Regulation (ESPR) represents a significant shift in the regulatory landscape for beauty brands operating in the EU.

This new regulation, published on March 30, 2022, marks a pivotal step toward promoting environmental sustainability and circularity in product design.

Key ESPR Compliance Elements

- Broad Scope: Unlike the Ecodesign Directive, which focuses on energy-related products, ESPR casts a broader net. It introduces a comprehensive framework for setting ecodesign requirements across various product categories, extending beyond energy to encompass aspects like product durability, reusability, recyclability, energy and resource efficiency, and more.

- Circularity and Sustainability: ESPR emphasizes circularity, beginning with the design stage to support reusing, recycling, and repurposing. Addressing issues at this early stage helps set lifecycle and supply-chain standards. This aligns with the growing demand for eco-friendly and sustainable products in the beauty industry.

- Digital Product Passport: The regulation introduces a novel concept – the “Digital Product Passport.” This tool offers information about a product’s environmental sustainability, making it accessible through data carriers. It details product attributes like durability, reparability, recycled content, and spare part availability, facilitating informed consumer choices and transparency regarding a product’s life cycle impact. At some point, information from suppliers, like ink manufacturers, could be required in the passport.

- Global Reach: ESPR’s rules apply to all products entering the EU market, whether produced within or outside the EU. This regulation acknowledges international trade rules, indicating the EU’s commitment to collaborating with producing countries to improve product sustainability. Start-up beauty brands in the United States must factor these requirements into their plans to reach EU customers.

What the ESPR Means for Beauty Brands Packaging in 2024 and Beyond

| ESPR Action | Description |

|---|---|

Elevated Sustainability Focus |

The EU ESPR Framework compels beauty brands to prioritize eco-friendly packaging, emphasizing durability, repairability, and recyclability. |

Expanded Accountability |

Beauty brands will be responsible for the entire packaging life cycle, participating in recycling programs and promoting recycled materials to minimize waste. |

Digital Product Passport Integration |

Beauty brands must leverage the Digital Product Passport to transparently communicate their packaging’s environmental impact. Embracing the requirement offers brands a new marketing moment with customers. |

Global Compliance |

Beyond the EU, beauty brands worldwide must meet these sustainability standards to access the EU market, posing both a challenge and an opportunity for global expansion. |

3. EU – Packaging and Packaging Waste Regulation (PPWR)

In late November 2022, the European Commission rolled out the draft Packaging & Packaging Waste Regulation (PPWR), a forward-thinking regulation aimed at diminishing packaging pollution and fostering a circular packaging economy.

In late November 2022, the European Commission rolled out the draft Packaging & Packaging Waste Regulation (PPWR), a forward-thinking regulation aimed at diminishing packaging pollution and fostering a circular packaging economy.

Key PPWR Compliance Elements

- Transition to a Regulation: The shift from a Directive to a Regulation ensures consistent implementation of packaging standards across EU Member States, eliminating variations.

- Extended Producer Responsibility (EPR): The PPWR harmonizes EPR obligations, defining key roles and introducing a national registration requirement for packaging producers.

- Packaging Design and Recyclability: The regulation mandates minimizing heavy metals in packaging and sets specific timelines for packaging recyclability criteria.

- Environmental Labelling: Packaging labels must include material composition, reusability, and system details for reuse and collection points. The regulation aims to unify labeling practices and facilitate the free packaging movement within the EU.

What PPWR Means for Beauty Brands Packaging in 2024 and Beyond

| PPWR Action | Description |

|---|---|

Standardized Sustainability |

The PPWR ensures standardized sustainability requirements for beauty brands’ packaging, promoting recyclability and reduced environmental impact. Beauty brands design packaging to meet these new standards. |

Extended Producer Responsibility (EPR) |

The PPWR harmonizes EPR obligations, defining key roles and introducing a national registration requirement for packaging producers. |

Packaging Design and Recyclability |

The regulation mandates minimizing heavy metals in packaging and sets specific timelines for packaging recyclability criteria. |

Environmental Labelling |

Packaging labels must include material composition, reusability, and system details for reuse and collection points. The regulation aims to unify labeling practices and facilitate the free packaging movement within the EU |

What U.S. Beauty and Cosmetics Product Exporters Need to Know for 2024 and Beyond

U.S. beauty product exporters with sights on UK and EU markets face increased compliance costs due to packaging regulations requiring investments in redesigning and meeting environmental standards. Challenges in securing recycled materials may add expenses, impacting competitiveness in the EU market.

Complying with these stringent regulations presents an opportunity for U.S. manufacturers to enhance their brand image, appeal to eco-conscious consumers, and gain a competitive edge. These regulations reflect the worldwide shift toward stricter environmental standards.

Compliance Costs

Beauty product manufacturers in the United States exporting to the EU must invest in compliance efforts to meet the packaging regulations’ requirements. This includes redesigning packaging to ensure recyclability, adhering to environmental labeling standards, and meeting extended producer responsibility (EPR) obligations. These compliance costs could affect the pricing and competitiveness of their products in the EU market.

Recycled Content Challenges

Meeting the EU’s mandates for increased recycled content in packaging materials may pose challenges for U.S. manufacturers because of the need to secure a reliable supply of recycled materials. This may involve additional expenses and logistical complexities.

Market Access and Competitive Advantage

Compliance with the EU’s stringent packaging regulations can give U.S. beauty product manufacturers a competitive advantage in the EU by enhancing their brand image and appeal to environmentally conscious consumers.

Global Implications

The EU’s packaging regulations represent a growing trend towards stricter environmental standards in global markets. U.S. cosmetics product manufacturers should anticipate that other regions may follow suit, necessitating similar adjustments to packaging and sustainability practices for international trade. Addressing these regulatory shifts proactively can better position them for success in a changing global landscape.

3 Steps To Improved Sustainability

In the face of increasing regulatory pressure, companies must balance the externalities. McKinsey outlines three stages of increasing complexity to introduce more sustainable packaging for FCMGs and, specifically, the beauty industry.

In the face of increasing regulatory pressure, companies must balance the externalities. McKinsey outlines three stages of increasing complexity to introduce more sustainable packaging for FCMGs and, specifically, the beauty industry.

Easy Wins

These straightforward efforts deliver results with little impact on operating costs or capital expenditures needs, functionality, or attractiveness of the packaging.

- Removing unnecessary packaging

- Light-weighting

- Increase the use of recycled content

- Introduce more mono-materials

Manageable Effort

Achieving results involves a 360-degree approach within the supply chain, including packaging converters and raw materials suppliers, to support a complete package redesign. These efforts can have cascading effects on shipping, consumer safety, and secondary packaging.

Heavy Lift

This part of the sustainable packaging equation requires broader changes within the packaging and recycling system. It comes with higher development and implementation costs, necessitating coordination across the value chain.

- Enhancing recycling infrastructure and technologies.

- Developing systems that support a circular economy.

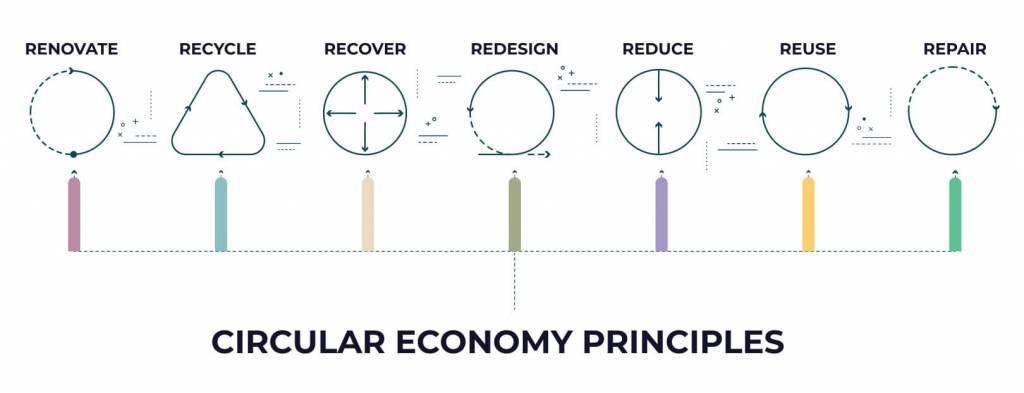

- Initiatives to drive behavioral change and increase awareness about recycling.

- Research and collaboration in developing new materials.

Printing and Inkjet Ink Solutions For Improved Sustainability

Get the free guide for Sustainable Inks

Download

Beauty packaging design extends to the quality and aesthetics of printing. Ensuring that labels, designs, and branding are vivid and eco-conscious is a top priority for beauty brands.

As packaging changes, printing OEMs, integrators, and ink manufacturers must react. Introducing new packaging designs and materials may require new ink choices or formulations. These players fall into the “Heavy Lift” category.

Further, if not today, brands may eventually turn to their suppliers to help them achieve stricter sustainability requirements. Here’s a look at how inks can fit into the sustainability equation.

- Direct Printing on Packaging: Inkjet ink formulations could help meet the UK and EU sustainability requirements and perform on packaging with energy- and space-saving printing equipment. Inks must dry or cure rapidly while delivering results with shelf appeal.

- Eco-Friendly Inks: As beauty brands make the shift to meet sustainability and consumer safety requirements, they are choosing inks free of harmful substances like PFAS and mineral oils. These safer and cleaner inks support recyclability and compostability. Clean inks support the beauty industry’s commitment to the product life cycle in a circular economy.

- Water-Based Inks: Once difficult to apply to non-porous materials without primers, water-based inks have evolved. New formulations, like LUNAJET® from Kao Collins, incorporate patented nano-dispersion technology that adheres to metal and plastic packaging. These inks offer vibrant colors while being water-soluble, reducing the environmental impact.

- LED Curable: LED curable inks have become popular for beauty brands, offering fast curing and reduced energy consumption. As companies incorporate thinner films in packaging, LED inks cure without the need for heat-generating UV-curing lamps.

- MOF – Mineral Oil Free: Beauty brands opt for MOF inks that exclude mineral oils, ensuring that the final product is free from potentially harmful substances. By using MOF inks, brands contribute to the safety and health of consumers while maintaining print quality.

- TIJ for HP and Funai: Thermal Inkjet (TIJ) solutions, compatible with HP and Funai technologies, provide beauty brands with reliable and cost-effective printing options for coding and marking. These solutions enable precise and consistent expiration dates, bar codes, and QR codes that could be used to comply with digital passports.

- Better Formulations for Improved Wetting and Coverage: Reducing ink consumption supports sustainability and reduces the costs of consumables. Beauty brands are seeking advanced ink formulations that offer superior wetting and coverage. By optimizing ink application, brands can enhance the visual appeal and cost-effectiveness of their packaging.

Cosmetics Packaging That Cares for the Earth

With the increasing demand for eco-friendly solutions, beauty brands are exploring packaging innovations that embrace aesthetics and environmental consciousness. Here are some viable packaging solutions for beauty brands.

Eliminate Labels – Direct Printing on Packaging: Aveda, a leader in natural beauty products, emphasizes sustainable packaging practices.

They utilize environmentally friendly materials and printing techniques, minimizing the use of labels.

Their commitment to eco-conscious packaging is outlined in their sustainability initiatives.

Use More Sustainable Labels – In a concerted effort towards sustainable packaging, beauty brands are increasingly turning to environmentally conscious labeling solutions.

Finnish beauty brand Lumene uses bio-based packaging, including a self-adhesive label made with a UPM Formi EcoAce wood-based material.

By adopting these eco-friendly labeling alternatives, beauty brands contribute to reducing the environmental impact of their packaging, aligning with global initiatives for a greener and more sustainable future.

-

More Sustainable Packaging – Leading the charge in sustainable packaging, Estee Lauder has been incorporating post-consumer recycled materials into its product packaging.

More Sustainable Packaging – Leading the charge in sustainable packaging, Estee Lauder has been incorporating post-consumer recycled materials into its product packaging.By doing so, they reduce their environmental footprint and set an example for the industry in adopting more sustainable packaging solutions.

-

Refillable Packaging – Another industry giant, Kao, has been at the forefront of refillable packaging. They offer customers the option to replenish their beauty products with refill packs, reducing the need for new packaging with each purchase.

Refillable Packaging – Another industry giant, Kao, has been at the forefront of refillable packaging. They offer customers the option to replenish their beauty products with refill packs, reducing the need for new packaging with each purchase.This innovative approach minimizes waste and provides cost-effective alternatives for consumers.

-

Research and Innovation Around New Types of Packaging – Unilever stands at the forefront of sustainability with ongoing research and innovation, exploring new types of packaging that are either on the cusp of entering the market or are still in development.

Research and Innovation Around New Types of Packaging – Unilever stands at the forefront of sustainability with ongoing research and innovation, exploring new types of packaging that are either on the cusp of entering the market or are still in development.Their commitment to reducing environmental impact drives initiatives focused on pioneering packaging solutions for a more sustainable future.

-

Package Design – Emphasizing package design, Kao strives to use less plastic. Eco-friendly film packaging called “air-in film technology” replaces rigid plastic containers with thin layers of film inflated and used like a bottle.

Package Design – Emphasizing package design, Kao strives to use less plastic. Eco-friendly film packaging called “air-in film technology” replaces rigid plastic containers with thin layers of film inflated and used like a bottle.The packaging design uses up to 50% less plastic than traditional bottles.

Eco-Proofing Beauty and Cosmetics Packaging

Forward-thinking brands have seen the writing on the wall. First adopting internal sustainability goals to meet consumer demands while expecting regulations to follow.

From eliminating labels and adopting innovative materials to eco-friendly printing solutions, the beauty world is making significant strides in harmonizing aesthetics with environmental responsibility.

At Kao Collins, we prioritize sustainability and strive to set the standard for the industrial inkjet ink industry. Contact us to discuss options to meet sustainability goals.