Oct 19, 2021

How to Make Industrial Inkjet Printing More Sustainable and Eco-Friendly

Truly sustainable development is defined as meeting the needs of the present without compromising future generations’ ability to meet their own needs. Sustainability goes far beyond inks in the printing industry, reaching into every aspect of the printing business — from the process to people to profitability.

After all, the business has to be profitable to be sustainable as well. That’s why Kao Collins and printing facilities aspire to hit aggressive benchmarks for sustainability and create a more responsible supply chain.

Why the Focus on Sustainability?

Kao Collins Eco-friendly Inkjet Inks Support Sustainability

Download

Sustainability has become prioritized by the printing industry to recognize the need to support a Circular Economy, a system aimed at eliminating waste and keeping products, equipment, and infrastructure in use longer.

Big Brands are Taking Action

The pressure on brands to address the waste associated with their products has been growing and will only increase. Companies such as Walmart, Target, Kao, and Unilever have adopted sustainability goals to reduce packaging materials. While attention has been focused on plastics and packaging, increasing attention has turned to the fashion industry and eco-friendly textile production.

Many of the world’s leading brands across various markets and industries are finding they can become more eco-conscious by implementing more sustainable printing and production processes for their products, packaging, labels, and other significant printing needs. These brands capitalize on the opportunity to become more sustainable through the end-products being manufactured for customers and the print industry’s ink manufacturing operations that produce the labels and packaging for those products.

How Kao Collins is Getting Involved

Kao Collins establishes a dialogue with customers to educate them about the current and future changes driven by pressure from consumers, consumer groups, environmental organizations, and government regulation.

Given the economic forces now applied to local municipal recycling programs, it is almost certain that governments will impose additional regulations on those that produce products, even if they are currently readily recyclable.

With the focus on packaging, paper, and textile waste increasing, Kao Collins’ printing operations have become engaged on several fronts. We are updated about the changes occurring concerning new substrates, advances in recycling technologies, and recycling services. This experience allows Kao Collins to offer solutions when customers prioritize sustainability and environmentally responsible corporate partnerships.

Evolving Inkjet Industry Regulations

Evolving Inkjet Industry Regulations

The inkjet printing industry continuously faces new requirements that support sustainability. In particular, these recent factors mentioned below have had a significant impact on the entire industrial printing ecosystem:

- Minamata and Mercury – The Minamata Convention on Mercury is a multilateral environmental agreement that addresses specific human activities contributing to widespread mercury pollution. Implementation of this agreement will help reduce global mercury pollution over the coming decades and challenge those in the printing industry using mercury lamps with their UV-curable inkjet printing systems.

- The Paris Agreement – The Paris Agreement is an agreement within the United Nations Framework Convention on Climate Change, dealing with greenhouse-gas emissions mitigation, adaptation, and finance, signed in 2016.

- Environmental Stewardship – Across the world, governments prioritize environmental stewardship for the larger good of the nation and our increasingly globalized economy.

- New Hazardous Materials Protocols – Organizations learn more about the effective management, prevention, and control of hazardous materials to protect workers from hazards; help avoid injuries, illnesses, and incidents; minimize or eliminate safety and health risks, and provide workers with safe and healthful working conditions.

Source: Sustainable Packaging Industries

Consumers are Demanding It

Consumers are more likely to conduct business with organizations that follow best practices for environmental sustainability. As markets become globalized and more competitive, simply offering a great product is no longer enough to win consumers’ favor. Shoppers want more than just product quality, and they often prefer the products and brands that align with their values and progressive global policies.

It seems obvious: Why would consumers support a brand financially if their business conflicts with their social and environmental values and they have access to suitable alternatives offered by competitors? In the face of imminent dangers of climate change, customers who want to be part of the solution are ready to consider the consequences of their shopping habits and factor them into their buying decisions.

Sustainability Affects Market Performance

Sustainability reporting, also known as environmental, social, and governance (ESG) reporting, has steadily grown in popularity over the past two decades. More and more investors and customers want to know what their brands are doing to help make the world a better place. It’s estimated that around 75% of S&P 500 (500 large companies listed on stock exchanges in the United States) publish ESG reports.

As more companies shift to ESG reporting, they often have to reconcile questions about their brand strategy. The critical questions raised in ESG discovery often lead to more significant questions about their company as a whole: Who are we? Are our mission, vision, and values aligned with our business goals?

See Our Bio-Based Mineral-Oil-Free Inks

Get Started

Organizations like Kao are increasingly applying their detailed ESG reports to analyze and identify material risks and growth opportunities for a global business in a more sustainable world.

According to JPMorgan Chase in the U.S., BNP Paribas in Europe, and DBS in Asia, the global pandemic spotlights the value of ESG considerations in capital markets. Global sustainability indices outperformed mainstream market benchmarks, and ESG investments achieved record inflows, pushing assets under management to a new high of more than $1 trillion.

Marketplace Sustainability Initiatives

In a circular economy, the goal is to eliminate waste and maximize the continual use of resources. The printing industry is about creating a sustainable, green printing process that considers inks, materials, production efficiency, waste, and recycling. The industrial printing process offers many opportunities to support these sustainability goals:

Printing on Recyclable Substrates

Notpla converts seaweed into biodegradable plastic.

There are emerging trends around the use and manufacturing of alternative substrates that are easier to recycle. Simultaneously, there is a movement to increase infrastructure recycling using existing technology and new technologies such as chemical recycling.

Some brands are shifting away from plastic and producing more paper-based products; examples include using paper-based material to replace six-pack rings. Procter & Gamble Beauty recently announced the plan to offer Old Spice and Secret brand deodorants in tube packaging that is all-paper, plastic-free.

Kao’s latest innovation in this field is recyclable film-based packaging for personal care products to eliminate rigid plastic bottles.

Additionally, Kao is working to make plastic containers and packages fully recyclable, including plant-based, biodegradable, vegan-friendly personal care products in a revolutionary eco-friendly package through Air Bottles, which reduces plastic usage by 50%.

There is a movement for textiles to use cellulosic fibers, recycled poly, organic cotton, and Better Cotton Initiative (BCI) cotton, a cotton sustainability program.

For labels that are being used on PET-based containers, there is a movement towards using labels compatible with recycling. Research is being done on new polymers that are more compatible with mechanical and chemical recycling for other plastics.

More Reusable and Responsible Packaging

In addition to new substrates and recycling technologies, companies are exploring reductions in packaging and package-free options. “Lightweighting” a package is not necessarily new, along with concentrating certain products to reduce package size.

New options being explored involve selling a single product with reusable packaging. Customers can refill the container with a super-concentrated product that the consumer reconstitutes.

A corollary to this approach is refillable packaging, where the consumer returns to the store to refill their container from bulk dispensing units. Smaller grocery stores are already exploring package-free options.

Methods for Achieving Sustainability

Sustainable printing methods are becoming more and more popular as individuals and businesses reduce their environmental footprint. Advances in technology allow print suppliers to produce sustainable printed material with no effect on quality.

Eco-Conscious Printing Technology and Printheads

Continuous inkjet technology (CIJ) and, increasingly, thermal inkjet systems (TIJ) are the printing industry’s popular solutions for coding and marking packaging for food, pharmaceuticals, and other consumer products. TIJ technology has a winning edge in achieving sustainability goals as TIJ printing reduces VOCs’ emissions by 90% and has wider acceptance accordingly.

Also, not all of the solvent ink used in CIJ systems is recaptured. Considerable amounts typically fall on printing equipment or the shop floor, which require additional solvents and other cleaning materials. In comparison, TIJ printing uses self-contained ink cartridges, which deliver only the ink necessary for printing and eliminate any accidental spillage risk.

Using More Water-Based Inks

See Our Water-Based LunaJet Inks

Get Started

Aqueous inks are made with water rather than solvents or petroleum-based chemicals. Water-based inks can be split into two main ingredients: (1) water and (2) dye or pigment.

Water-based inks serve as a great alternative to solvent ink in many circumstances, and it is a much greater option for sustainability. They are easier to clean up and print very nicely; meanwhile, oil-based ink, while sometimes easier to work with, has to be used carefully and requires mineral oil for cleanup.

Traditional Water-Based Inks

Water-based printing inks are a durable, high-quality option for printing onto substrates such as documents, non-glossy paper, corrugated cardboard, wood and lumber, and coated substrates.

Water-Based LUNAJET Ink for Printing on Flexible Film Packaging

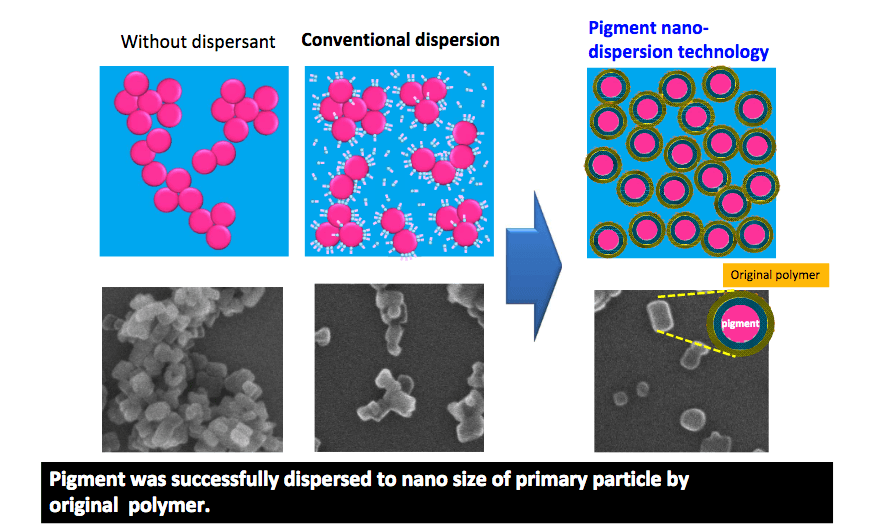

Kao Collins’s LUNAJET water-based pigmented inkjet ink can significantly reduce VOCs (volatile organic compounds) emitted during the printing, compared to conventional solvent-based ink, thanks to its unique nano-dispersion technology.

This ink makes a significant contribution to improving the environment for workers and reducing the global environmental impact.

While food manufacturers have discovered LUNAJET Ink delivers better results on flexible and shrink-sleeve food packaging, they are also a more sustainable option for printing on flexible film packaging compared to UV-curable ink formulations.

Soy Inks for Inkjet Printing

While soy inks are produced from the versatile agricultural product, it still falls short of being a truly “green” product. However, they are more biodegradable than petroleum-based inks.

Using Sustainable Printing Equipment

Replacing Mercury-based UV-curable Inkjet Systems

Replacing Mercury-based UV-curable Inkjet Systems

Concerns about mercury poisoning’s danger affecting the central nervous system have given rise to UV-curable Inkjet Systems’ alternative, mostly in the food industry. Besides, UV-curable systems using mercury lamps consume more energy.

Alternative LED and nano water-based inks reduce energy consumption and corresponding costs, thus supporting sustainability efforts.

Read More: 3 Options for Replacing Mercury-based UV-Curable Inkjet Systems

Hybrid Inkjet Solutions

Hybrid printing will be the key contributing factor in sustainability as it enables more work to be done in a shorter time. Hybrid systems deliver cost-effectiveness too.

The most frequently used industrial printing methods emphasize the advantages of hybrid approaches over individual methods. Hybrid systems can help industrial printers handle dynamic variables such as stakeholder preferences, interconnected or contradictory criteria, and uncertain environments. The hybrid approach improves decision-making related to sustainability issues while also promoting the printing systems’ future application.

Read More: The Advantages of Flexo-Inkjet Hybrid Printing Systems | Case Study: Colordyne-Kao Collins Hybrid Partnership

Direct to Object digital printing of SKU (A stock-keeping unit scannable barcode)

Consumer safety and increasing government regulations have created new opportunities in direct-to-object digital printing, reducing reliance on label production and material waste.

Water Usage and Sourcing

Typical water usage for screen printing, with wash-offs, high volume, and wastewater, is in the region of 50-60 liters of water per meter. Digital printing, with its minute quantities of ink and its requirement for fixation-only finishing, can use less than 2 liters of water per meter. Every liter of water from screen printing is contaminated with VIOL’s (volatile inorganic liquids) or with resins or waste ink. It requires substantial investment locally to allow discharge into the wastewater system.

Digital textile printing offers a relevant and sustainable path for the future.

Energy Usage

Reducing energy consumption for any manufacturing facility is an essential step towards sustainability, especially for commercial printing. Current printing press technology has dramatically improved energy efficiency and reduced the environment’s impact by cutting waste to a minimum. High-capacity presses and post-production machinery can be wasteful if energy consumption is not taken into account. Not to mention the cost of cooling and heating a large warehouse space.

Greenhouse Gas Emissions

Many commercial print applications – book publishing, newspaper and magazine production, paper-based marketing material, and numerous others – are characterized by high over-production and waste levels. Printed matter is manufactured and distributed to end-users, retailers, and warehouses, where a proportion is unwanted or loses its value before being sold.

Subsequently, obsolete printed material is recycled or discarded as waste. This occurs primarily due to business models built around traditional large-scale offset litho, web offset, and other analog print technologies, which have evolved to deliver a very low cost per page on large print runs.

Newer digital press technology has the potential to re-engineer print business models and eliminate much of this waste.

Despite this low cost and low environmental impact during use, paper has significant embedded greenhouse gas (GHG) emissions resulting from other phases of the paper’s life cycle. In fact, in most print applications, including those mentioned above, paper is the dominant contribution to GHG emissions.

Although alternatives to paper such as e-books, e-paper, and erasable ink have been proposed, it is not clear that these will succeed or that they will reduce emissions; it would certainly be unwise to rely on them as the sole route to abatements. Our sustainability goals are supported by quantifying GHG emissions due to inefficiencies in current commercial and office print applications and improving business models built on digital print and distribution technologies to conserve paper and enable GHG reductions.

Paper Sourcing and Weight

Factors like lighter paper require different inks or fewer inks for printing, improving the sustainability of printing on this paper.

Leading brands in the printing industry are committed to the recycling process, and paper is one of the most recycled resources in the world. Studies show that recycling a single ton of paper can save up to 7,000 tons of water, 380 gallons of oil, 17 trees, and 4,000 kilowatts of energy.

Some other benefits of paper recycling strategies include:

- Extending the supply of wood fiber in circulation

- Reducing greenhouse gas emissions released when paper decomposes

- Limiting the amount of energy required to produce paper products

- Saving landfill space

- Reducing the energy required to create new paper products

Using Less Ink When Printing

Applying only the precise amount of ink necessary to produce the required printing results is the most desired way to save on cost and sustainability efforts. Managing ink usage supports sustainability, produces better quality, and saves money. Over-inking produces dot gain and bleed-through.

Read More: How To Use Less Ink When Printing

Reducing Waste

The diverse inkjet industry prints on a wide range of substrates, such as paper, polymers, metals, etc., using a broad range of printing technologies. Wide variations exist between printers’ waste management practices and the amounts of waste they send to landfills.

For example, bulk supply systems eliminate cartridge disposal.

Also, printers using siliconized papers for non-stick backings for labels find no recycling option waste material. This is also the case for printers using carbon paper. Waste reduction remains an integral part of the sustainability management system in the printing industry.

These factors are commonly examined when measuring waste, especially relating spoilage amounts to waste and amounts destined for recycling and disposal:

- Post printing activities such as laminating, cutting, wrapping, and packaging the printed product offers potential opportunities to minimize waste generation.

- Identify acceptable waste avoidance practices for preparation in case studies.

- Provide a range of standard but practical methods to measure wastes.

- How to avoid and better manage substrate waste and post-printing wastes

- How to better manage hazardous waste; its legal requirements, avoidance, generation, management, recycling, and disposal.

- Provide case studies on effective waste management and cost management issues.

Certifications for Sustainability

Businesses that use or are involved with the industrial printing process can obtain several certifications to demonstrate their commitment to operating more sustainable and environmentally friendly.

Global 100 Most Sustainable Corporations

Announced on January 21 at the Global Economic Forum Annual Meeting (or the “Davos Forum”) held in Davos, Switzerland, the Global 100 Most Sustainable Corporations in the World represents the world’s top 1.3% of organizations as measured by sustainability performance.

Kao Corporation has once again been selected as a Global 100 Most Sustainable Corporation from a pool of 7,395 companies chosen for sustainability evaluation in 2020 at Corporate Knights, a Canadian media and research company that developed the index evaluating global companies’ sustainability performance.

Sustainability as Corporate Culture

The purpose of adopting sustainability into corporate culture is multifold. It enables researchers to explore the influence of their brand on green initiatives’ outcomes in business performance. Sustainability-based brand knowledge also drives customers favorably towards the brand and improves the long-term performance of the firm.

Kao’s corporate philosophy involves the commitment to Yoki-Monozukuri, promoting technological innovation in the consumer goods and chemicals industries, and contributing to the natural world’s sustainability.

Looking Ahead

Kao focuses on Sustainable Development Goals (SDGs) that have been agreed upon and adopted by the international community. As key performance indicators for realizing a sustainable society, these SDGs set forth an integrated approach for improving the environment, society, and economy. The involvement and support of leading brands and companies are extremely important to achieving these SDGs, and Kao Collins is committed to continuing our pursuit of sustainability accordingly.

Contact Kao Collins to learn more about inkjet ink options that support your organization’s sustainability goals.

Frequently Asked Questions

Are UV inks environmentally friendly?

UV inks are environmentally friendly because, unlike solvent-based inks, 100% of the ink is used. The UV radiation from a light source activates photoinitiators to convert the liquid into a solid.

What inkjet inks release no or low VOCs

Generally, water-based inks release no or low VOCs. Other eco-friendly inks with no or low VOCs include vegetable and plant-based inks, UV/LED-curable, and Electron-beam curable inks.

What are bio-based inks?

Inks that are formulated with compounds containing renewable and primary biological sources, in particular of plant origin: woodworking waste, corn, and more. They generally do not contain synthetics, toxins, or environmentally damaging substances. These inks are often referred to as mineral-oil-free ink (MOF).

Download Our Guide to Inks for Improving Performance